The Pappalardo Apprentice program pushes the boundaries of the traditional lab experience, inviting a selected group of juniors and seniors to advance their fabrication skills while also providing mentor training and peer-to-peer mentoring opportunities in an environment fueled by creativity, safety, and fun.

“This apprenticeship was largely born of my need for additional lab help during our larger sophomore-level design course, and the desire of third- and fourth-year students to advance their fabrication knowledge and skills,” says Daniel Braunstein, senior lecturer in mechanical engineering (MechE) and director of the Pappalardo Undergraduate Teaching Laboratories. “Though these needs and wants were nothing particularly new, it had not occurred to me that we could combine these interests into a manageable and meaningful program.”

Apprentices serve as undergraduate lab assistants for class 2.007 (Design and Manufacturing I), joining lab sessions and assisting 2.007 students with various aspects of the learning experience including machining, hand-tool use, brainstorming, and peer support. Apprentices also participate in a series of seminars and clinics designed to further their fabrication knowledge and hands-on skills, including advancing understanding of mill and lathe use, computer-aided design and manufacturing (CAD/CAM) and pattern-making.

Putting this learning into practice, junior apprentices fabricate Stirling engines (a closed-cycle heat engine that converts thermal energy into mechanical work), while returning senior apprentices take on more ambitious group projects involving casting. Previous years’ projects included an early 20th-century single-cylinder marine engine and a 19th-century torpedo boat steam engine, on permanent exhibit at the MIT Museum. This spring will focus on copper alloys and fabrication of a replica of an 1899 anchor windlass from the Herreshoff Manufacturing Co., used on the famous New York 70 class sloops.

The sloops, designed by MIT Class of 1870 alumnus Nathanael Greene Herreshoff for wealthy New York Yacht Club members, were a short-lived, single-design racing vessels meant for exclusive competition. The historic racing yachts used robust manual windlasses — mechanical devices used to haul large loads — to manage their substantial anchors.

“The more we got into casting, I was modestly surprised that [the students’] exposure to metals was very limited. So that really launched not just a project, but also a more specific curriculum around metallurgy,” says Braunstein.

Metallurgy is not a traditional part of the curriculum. “I think [the project] really opened up my eyes to how much material choice is an important thing for engineering in general,” says apprentice Jade Durham.

In casting the windlasses, students are working from century-old drawings. “[Looking at these old drawings,] we don’t know how they made [the parts],” says Braunstein. “So, there is an element of the discovery of what they may or may not have done. It’s like technical archaeology.”

“You’re really just relying on your knowledge of the windlass system, how it’s meant to work, which surfaces are really critical, and kind of just applying your intuition,” says apprentice Saechow Yap. “I learned a lot about applying my art skills and my ability to judge and shape aesthetic.”

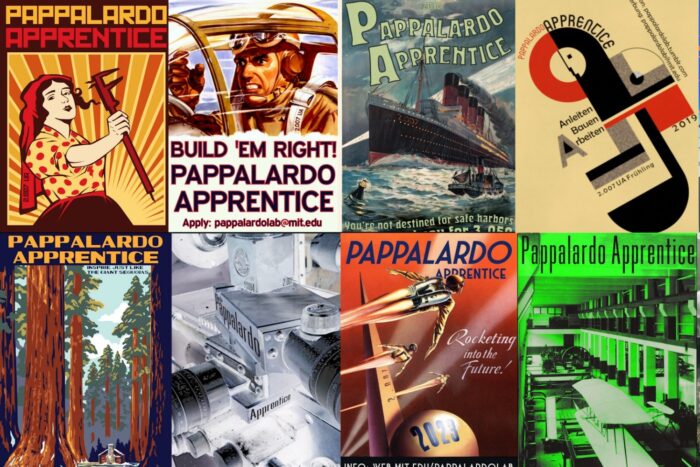

Learning by doing is an important hallmark of an MIT MechE education. The Pappalardo Apprentice Program, which celebrated its 10th year last spring, is housed in the Pappalardo Lab. The lab, established through a gift from Neil Pappalardo ’64, is the self-proclaimed “most wicked labs on campus” — “wicked,” for readers outside of Greater Boston, is slang used in a variety of ways, but generally meaning something is pretty awesome.

“Pappalardo is my favorite place on campus, I had never set foot in any sort of like makerspace or lab before I came to MIT,” says apprentice Wilhem Hector. “I did not just learn how to make things. I got empowered … [to] make anything.”

Braunstein developed the Pappalardo Apprentice program to reinforce the learning of the older students while building community. In a 2023 interview, he said he called the seminar an apprenticeship to emphasize MIT’s relationship with the art — and industrial character — of engineering.

“I did want to borrow from the language of the trades,” Braunstein said. “MIT has a strong heritage in industrial work; that’s why we were founded. It was not a science institution; it was about the mechanical arts. And I think the blend of the industrial, plus the academic, is what makes this lab particularly meaningful.”

Today, he says the most enjoyable part of the program, for him, is watching relationships develop. “They come in, bright-eyed, bushy-tailed, and then to see them go to people who are capable of pouring iron, tramming mills, teaching other people how to do it and having this tight group of friends … that’s fun to watch.”

Have a question about this article?

Contact Sarah Foote from the Division of Student Life’s Communications Office at dsl-comm@mit.edu